Elcam continuously strives to improve product offerings and supporting services. In this edition of our newsletter, we highlight Elcam’s solutions for ORTHOPEDICS and our state of the art manufacturing capabilities, as well as share updates of Elcam's current situation.

Elcam Stands Strong– Update #8

As we navigate through the seventh month of the conflict in Gaza, we remain hopeful for peaceful times ahead. We want to assure you that despite the ongoing situation, Elcam Medical has maintained a stable routine, ensuring that our operations continue without interruption.

We are pleased to report that all Elcam facilities are operating at full capacity. Our logistics remain secure and on schedule, with no disruptions in our supply chain. The safety and well-being of our employees are paramount, and we have ensured that all necessary measures are in place to keep our teams safe.

In recent months, we have observed a significant increase in personnel presence at our facilities in both Bar’am and Dalton. This return to the workplace, despite the option to work remotely, is a positive indicator of our gradual return to routine operations. This shift underscores our commitment to maintaining the highest standards of production and service.

As part of our ongoing commitment to resilience and strategic growth, we are excited to announce the initiation of a project to add another manufacturing facility in Central America. This expansion is an important layer of our contingency plan, which has already proved its effectiveness. This new facility will enhance our capability to serve you better and ensure even greater reliability of supply.

We are continually monitoring the situation and are prepared to make any adjustments necessary to ensure the safety of our employees and the continuity of our services to you.

Thank you for your continued trust in Elcam Medical. We are committed to keeping you informed and ensuring that our partnership remains strong, even in these challenging times.

New production site in Central America

Elcam remains committed in its dedication to operational excellence and, in accordance with our contingency plan, we are enhancing our strategic initiatives for the future. This entails progressing, as previously communicated, with our plan to establish a new manufacturing facility in the broader vicinity of Central America to further fortify our resilient supply chain.

We are pleased to announce that a decision was reached in late May to designate the Dominican Republic as the country for this endeavor. This location was chosen due to its status as a central hub for medical device manufacturers, enabling us to better serve our customers in North America.

Currently, we are in the process of identifying the precise industrial park within the Dominican Republic. Once this selection is finalized, construction of the facility will begin promptly. Elcam anticipates commencing local production in the third quarter of 2026.

Orthopedics

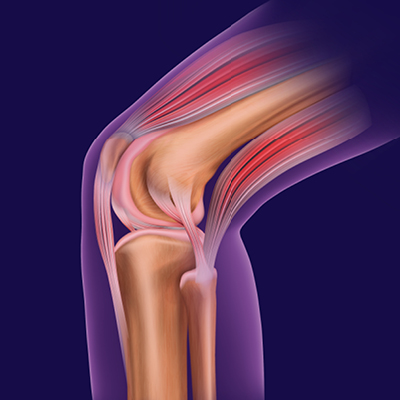

Elcam has recently entered the world of Orthopedic care which encompasses the diagnosis, treatment, and rehabilitation of different musculoskeletal conditions.

As a long-time provider of solutions for critical care, Elcam is well aware of the importance of high quality treatment and tailor-made solutions and plans to use its vast experience and knowledge to meet the specific needs of orthopedics.

A-TapTM

A-Tap™, Elcam Medical’s innovative solution for intra-articular injections offers precision, efficiency, and enhanced patient comfort.

Research shows that up to 20% of intra articular injections miss the right site, leading to suboptimal treatment and ineffective pain relief. With A-Tap, physicians can ensure that medication is delivered precisely where needed, thanks to the backflow technique and minimal needle movement that verifies and maintains correct placement

Part of Elcam’s launching program is dedicated to working with distributors. See below how one of our distributors is introducing and educating his staff on working with the A-Tap

A-Tap is 510 (k) cleared and CE approved

Learn more

Elcam’s Automation Capabilities

Elcam is a leading manufacturer of top-tier disposable medical devices and accessories tailored for the OEM market. Central to our ability to uphold unparalleled quality is Elcam’s reliance on automated injection molding and assembly processes throughout production.

Cutting-edge tooling, multi-cavity molds, and two-component molding in adaptable injection machines fabricate the necessary components, which are subsequently assembled in Elcam’s fully automated assembly lines. This entire procedure adheres rigorously to stringent quality control measures until the products are prepared for dispatch from our warehouses.

Consequently, every Elcam client can be confident that the medical devices he receives not only meet but exceed the most rigorous standards, ensuring their suitability for application.

Best regards,

Igal (Guli) Kohn, CEO and General Manager

Exhibitions

Congreso AEA-SEROD

26-28 June

Barcelona, Spain

Booth 36

(with Enelini Associats)

Medtec China

25 – 27 September

Shanghai, China

Booth 2D001