Stopcock Overview

Professionals sourcing medical disposable stopcocks know that it is a critical device that needs to be sourced from the experts.

Elcam Medical, the world leader in OEM stopcocks, offers you the widest range of Stopcocks and Manifolds for all fluid control related applications.

Elcam Stopcocks™ is our sub brand enhancing the solid track record of our leadership in this field and our 40 years of experience and expertise in developing and manufacturing medical disposable stopcocks, resulting the benefits professionals value so much: Broadest portfolio, innovation, seamless integration, customer experience

Broadest Portfolio

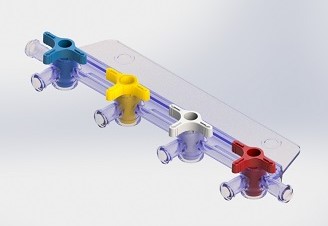

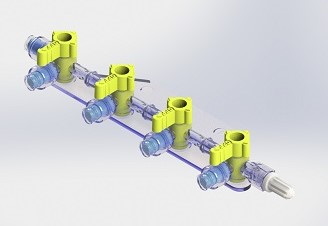

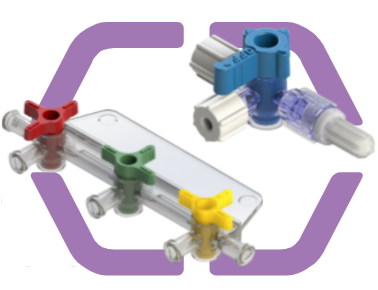

Elcam Stopcocks™ is renowned for the broadest range of stopcocks and manifolds in the industry, offering unmatched configurations, flow rates, handle styles and variety of high performance materials.

3 Way Stopcocks

Elcam Medical is a world leader of OEM stopcocks. We offer our customers the widest variety of Stopcocks that fit all the fluid control related applications.

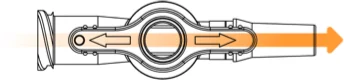

3 way stopcocks or taps is the customary terminology used for describing a stopcock with 3 ports.

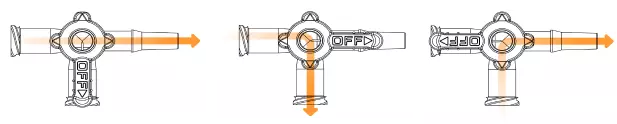

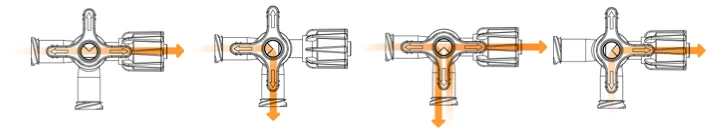

These are the most commonly used stopcocks in a variety of medical applications. 3-way stopcocks can be further divided according to the handle rotation – 90°, 180° or 360° and number of handle positions available (2-4).

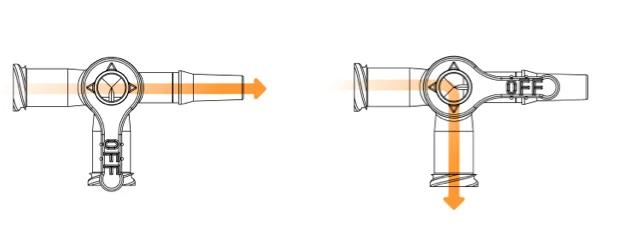

While most will refer to "3Way Stopcock" as a generic name for all stopcocks with three ports, the official terminology is referring to the number of flow directions as shown in the adjacent diagrams:

Elcam's broad range of stopcocks are designed to meet the requirements of I.V therapy including high flow systems, anaesthesia, hemodynamic pressure monitoring, angioplasty and other medical applications.

Elcam's Standard Stopcocks can be supplied in 1,2,3 and 4 way configurations, with different handle colors and styles to match a variety of applications.

Our stopcocks are available in different materials including high resistance Polycarbonate grades, Polysulfone and Tritan compatible with lipid based admixtures according to customers’ requests. The Stopcocks are suitable for Gamma irradiation and ETO.

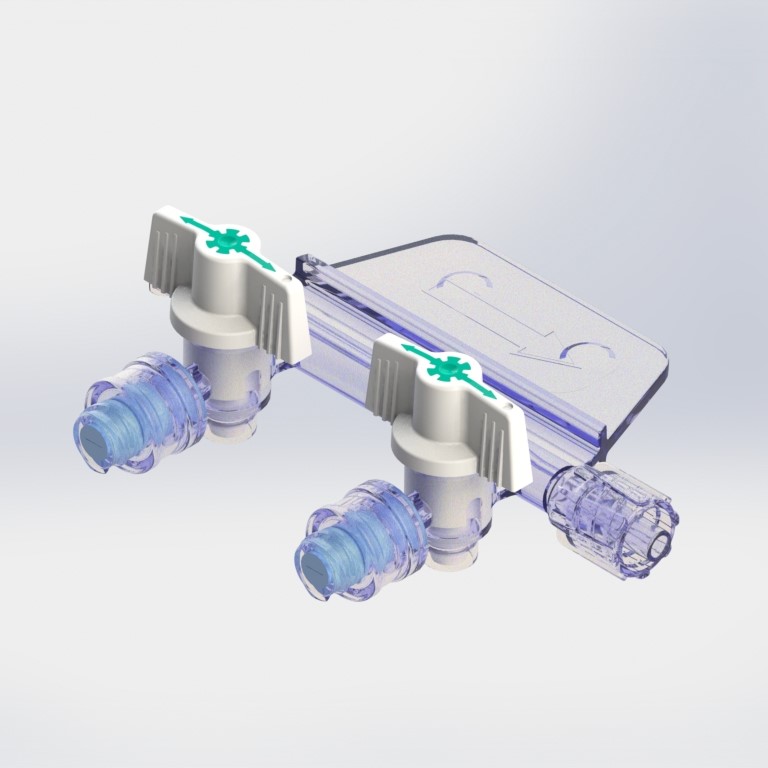

Innovation - commitment to safety

As a worldwide leader in OEM stopcocks, Elcam continuously strives to create better solutions to real flow control safety problems by combining clinical and engineering knowledge acquired over the years. The Elcam Stopcock road map is a tool we use to assure continuous improvement of our stopcocks – from lipid resistance and free of any hazardous materials through solutions for secured connections and up to infection control. Our innovative Marvelous™ (MRVLS) stopcock developed to enhance patient and care giver safety is an excellent example, emphasizing the competitive advantage and differentiation you gain when selecting Elcam Stopcocks™.

Seamless Integration

Sometimes the burden of integrating a new medical component into your product seems like it isn't worth the effort. In the case of Elcam Stopcocks™, we can take much, if not all of this burden, from you:

- Repeated quality minimizes the risks of flaws and complaints

- Customization of our stopcocks according to your exact needs.

- Tailoring the Validation & Verification plan according to your requirements and taking the burden of V&V plan execution upon our shoulders

- Providing you with the documentation needed for your regulatory requirements

- Fully developed project management and service, cushioning the bumps many integration projects usually face.